Case Study: Satterfield & Pontikes Construction, Inc.

See how Satterfield & Pontikes Construction leverage Inertia and Procore technology to increase efficiency, save time and money.

The Contractor:

Privately-owned Satterfield & Pontikes Construction, Inc. (S&P) at www.satpon.com provides a full range of pre-construction, construction and consulting services and a number of delivery methods including General Contracting, Construction Manager at Risk, and Design-Build. Serving both the public and private sectors regionally and nationally, S&P is an innovator in construction management systems and has pioneered numerous technological advancements across its solid portfolio of wide-ranging projects, including educational, transportation, healthcare, commercial, governmental as well as retail distribution and manufacturing facilities. In addition to its headquarters in Houston, S&P has offices in Dallas and in San Antonio which services Central Texas, including Austin. The company also has Business Units in Los Angeles and in New York.

The Challenge:

As a leader in deploying and building technology to optimize the construction process, S&P has been taking advantage of BIM and Procore to ensure timely and on-budget projects. But, as with every step forward, challenges arise, in the case of S&P, the challenges are two-fold:

-

Procore simplifies workflows but it is difficult to coordinate and visualize the job status by location - Procore delivers a breadth of functionality covering many workflows of the construction project. However, as one creates records in Procore and wants to correlate that information by location - for example: one wants to see all RFI’s and observations still open on a wall before wall close-up. The process can be time-consuming and difficult to ensure all information is readily available, resulting in hours per day needed to understand the current state of the project and more importantly can lead to missed items and costly rework.

-

BIM is powerful but difficult to extend to the field - The fidelity of data in the Building Information Model can be of high value but it is difficult to deliver that information to the field in a manner that is easy to access and take action on. Today, a variety of tools are needed to find and correlate the information which is difficult and requires expertise not normally found in the field. This lack of information in the field leads to requests flowing back to the VDC team with all the resulting delay and overwhelming a very limited resource.

The Approach:

S&P looked to implement Inertia Systems Intelligent Construction Drawings (ICDs) to address both challenges of delivering BIM to the field and attaching Procore information to locations to make quick and timely decisions on their projects.

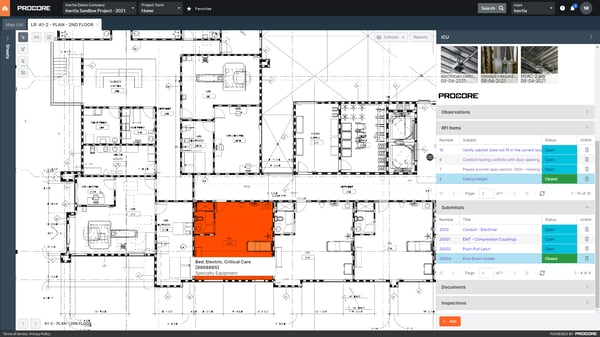

Inertia extracts the information from the BIM model, preserving the relationship between objects such as floors, rooms, walls, doors but presented in Procore in a more familiar 2D drawing representation. Inertia preserves not only the objects and their relationships but it also presents the properties associated with those objects in an easily consumable side panel. Click on an object, for example a room, and quickly see all the properties associated with it. This while never having to navigate away from their Procore workspace.

As Trevor Brown, Project Manager at Satterfield & Pontikes pointed out when using Inertia’s ICDs, “Instead of having to go through shop drawings or other documents, you can be out in the field with Inertia and click on a duct on the Inertia ICD location map and you can see all the relevant properties captured from the model such as elevation.”

In addition to bringing the model information to the field in a consumable and relatable format, Inertia also visually sets and aggregates statuses and Procore workflow information in the same Intelligent Construction Drawings. As S&P has discovered, it is time-consuming to aggregate all the information that exists throughout Procore and possibly external information as well to accurately determine the status of a project.

By again utilizing the Inertia ICDs, Trevor observed that, “Using the customizable checklists built-into Inertia, we can see a 2D plan and see, for example, the status of wall close-ups. Is the in-wall rough-in complete? Has it been inspected? This is a very cool feature of the color-coded visual reporting. You are still connected to the project and the current workflows instead of jumping between multiple places in Procore.”

Trevor continues, “ICDs highlight in simple colors, what’s good, what’s bad without having to jump to 7 or 8 different places in Procore. This saves several hours per day, just to be able to pull up all the information as well as avoiding the interruptions inherent in spending several hours looking for information. With the ICDs, I can see information immediately and get the answers I need. This saves time for the other field level team including other Project Managers, Superintendent, Field Engineers and Project Engineers.”

“Using the customizable checklists built-into Inertia, we can see a 2D plan and see, for example, the status of wall close-ups. Is the in-wall rough-in complete? Has it been inspected? This is a very cool feature of the color-coded visual reporting. You are still connected to the project and the current workflows instead of jumping between multiple places in Procore..”

The Result:

Utilizing Inertia ICDs, S&P was able to realize the following benefits:

- Field team members can save hours per day by:

- Finding relevant Procore records on Intelligent Construction Drawings locations, information that is normally scattered across multiple Procore tools that are not currently connected.

- Color coded status overlays of the Intelligent Construction Drawings to show status of the project quickly and easily, is this room ready for punch, is this wall ready to close - all answered visually

- Information contained in BIM is easily located and available in the field

- Field users can view properties from the model without navigating a complex 3D model or posting requests to the overtaxed VDC team to respond.

- The elements in the model are presented in a familiar 2D drawing format and their associations are preserved so users can easily find related objects, for example: pick a door and ask the ICD to show all the other drawings that have the same door, or to see all similar doors on this sheet or all sheets and immediately see the results.

S&P plans to expand the use of Inertia on similar projects going forward. They also plan to apply the flexibility of the Intelligent Construction Drawings to more phases of the construction project including pre-construction for buy-out and close-out to deliver aggregated and correlated information to the owner on completion.

To find out more about the power of Intelligent Construction Drawings request a live demo below.